Little Sibling

Should a fabrication space be expressive? Should it showcase the possibilities of current technologies? Certainly, there are many such shops located inside generic warehouses whose primary function is to allocate adequate space for all sizes of equipment, equipment typically delineated by yellow safety tape. In the case of the new Prairie View A&M University (PVAMU) Fabrication Center, however, Houston firm Kirksey Architecture offers a formal language for this emerging typology.

“The Fabrication Center is arranged as, essentially two parallel bars, one housing traditional shops and the other digital shops, with the main assembly and collaboration area between,” says senior project designer Gary Machiceck, AIA, of Kirksey. The facility is reserved for students at the School of Architecture, which is right next door. It has been, in the words of Dean Ikhlas Sabouni, a “dream come true.” The impetus for the building was driven in part by the former shop supervisor for the school, Sam Smith, who informed the dean that the school had outgrown the original shop and that he was concerned about student safety. These issues were addressed by a design studio led by professor Bill Price, who challenged his students to think about the future of fabrication; they then presented their ideas to the school and PVAMU administration.

After an initial programming exercise, PVAMU released a Request for Proposals and selected Kirksey for the design. At 25,000 sf, the fabrication building is the most capacious and well-equipped facility of its kind at any school in Texas — with robotic arms, 5-axis CNC, multiple laser cutters, 3-D printers, and waterjet for nearly any conceivable material. The icing on the cake is that access and materials are unlimited to the students. Visiting during midterms, I expected the building to be abuzz, and yet it was strangely quiet; suggesting the equipment is being utilized tentatively.

The fabrication building is conceived as a “prairie,” in contrast to RoTo Architects’ design of the neighboring architecture school, which conceptually is a “canyon.” That building is hollowed to expose the elements of its composition — a compelling and convenient teaching device for a school of architecture. The fabrication building echoes many of the earlier building’s material selections, most notably the use of brick and steel. Where the brick at the architecture school is fluid and eroding, in the fabrication building construction it is stacked and pulled, foregrounding another more tempered potential of the material. The parabolic metal mesh at the school is picked up in a tessellated standing-seam roof at the fabrication building, lifted from the ground plane to mimic the movement of the prairie.

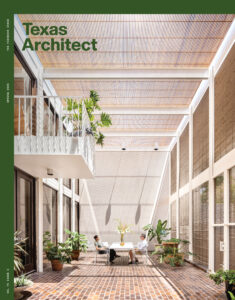

Placed to the east of the architecture school so as not to obstruct the view as one approaches via University Drive, the fabrication building opens with a porch on its northwest side — a large overhang and the apotheosis of the design. Kirksey did a number of solar studies on the form of the roof to optimize it for the summer months, ensuring that the building would be shady and comfortable in the Texas heat; however, the visual effect is to nearly obscure the front entry, which gets lost in the shade of this overhang.

While the fabrication center’s “front” addresses the architecture school, its “rear” faces southeast and includes a generous loading dock. Here, the notion was that entire wall sections — or even full (albeit small) homes, such as those assembled by students working with the innovative Shelly Pottorf — could be deployed from the fabrication building itself, yet another enviable attribute of the program. Regrettably, due to safety concerns, this back face is fenced off from the rest of the campus in a rather banal and inconsiderate manner. To compound the issue, most visitors and students at the school arriving by car are likely to park in this lot and will be forced to move around the loading area and the two most uninviting walls of the building, which are mostly solid brick with small clerestory windows.

Having an older sibling can be a lot to live up to. In the aforementioned material choices, in siting and even in conceptual positioning, the fabrication building defers to the architecture school. This direct response to so many design cues inevitably invites comparison. An easily referenced model has been set with the expectation of at least meeting similar standards, while distinguishing a unique path. Kirksey has done an exemplary job of designing a support facility that is rightly the envy of architecture schools across the nation. By all current standards of comparison, the fabrication building at PVAMU surpasses expectations, and it took home an AIA Houston Design Award, last cycle. Nevertheless, at present, PVAMU’S Fabrication Center remains one full of potential that has yet to grow out of the shadow of its neighbor.

Jesse Hager, AIA, is principal of CONTENT Architecture in Houston and chair of the TxA Publication Committee.