Teaching Building

The San Jacinto College (SJC) North Campus is on the east side of Uvalde Road; the new Center for Industrial Technology (CIT) is located on the west. A four-lane highway cuts through fallow fields and is bounded on either side by overhead power lines like bumpers in a bowling lane. It heralds its arrival at the campus with a turn lane. Conventionally sited, a field of parking accommodates the cars coming from US-90, and directions to the new CIT are best given as “across from the rest of campus.” However, this materially elegant building marks the beginning of a potentially rich chapter of the college’s life focused on vocational schooling, a training that should by its nature be in tune with the most efficient use of the best resources at hand.

The product of a bond vote, this building was intended, according to Bryan Jones, Associate vice chancellor of facilities services for SJC, to be attractive yet functional, tasteful, and sophisticated. It was designed by Huitt-Zollars to “build brand image but not be gold-plated.” It is a prototype — one that has recently been experimented with elsewhere, but with vastly higher budgets and equal uncertainty as to future use. Jones admitted that the programming document had seen at least 2 1/2 iterations, adding that this was in part due to recognizing the value the architects brought to the table, identifying shortfalls, and then backtracking to identify solutions — all on a constrained timeline.

A hybrid system of tilt-up concrete and steel with brick and glass infill proved to be both cost-effective and conducive to the large high bay structures speculated to be required. Over the design and occupation of the project, different programs began to occupy the bays marked by the top-heavy concrete panels and a truss system of roof windows letting natural light pour in while setting up a rhythm for the overall structure. None of the interior walls are load-bearing. “We joined small tilt wall panels with long-span trusses,” says design director William Truitt, AIA. “That way the exterior would alternate between concrete and masonry that faces the campus, and the high bay labs could be configured in any way now or in the future as the program changes. And it will change.” As late as move-in day, the architects were responding to new equipment acquisitions and private partnerships that continue to contribute through sponsorship of classes and programs.

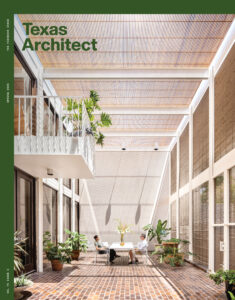

Usually notoriously flat, the unorthodox distribution of the tilt-wall panels allowed for variation and mixing of complementary materials along the facade for depth. By adding a simple vertically striated form liner to some of the panels, the architects were able to extend this language further. The panels embrace neighboring elements, often windows, with a slight overlap to the south, never a conventional punched opening. This trope can be identified on the interior as well as exterior of the building, providing the occupants with a subtle sense of position. Breaking up the plane of the east wall is a small courtyard separating the faculty offices on the second floor from the classrooms overlooking the shop spaces below. This small move frames a deck that contributes formally to the building by breaking down the scale to that of the campus across the street.

Brick infill between concrete panels and glass responds to the material language of the original campus and is used here to great effect. The entry is marked by a pattern of pulled brick creating shadow and texture while signifying approach. A horizontal datum is struck between upper and lower levels, allowing an understated stepped shift in the wall and vertical relief uncommon to a tilt-up building. While the remaining elevations are relatively banal, the allocation of the various materials within a seemingly rigid system gives even the longest walls a disarming cadence and betrays a compositionally deft hand.

This classroom overlooks the lab space. Photo by Paul Hester.

A teaching building in the truest sense, on the interior all of the systems are left exposed, from structural to mechanical, electrical, and plumbing. On axis with the entry, a high bay proudly displays robotics and hints at what is to come. Just beyond, the next lab contains a Kubrickian network of red welding cells and individual exhausts routed and consolidated with a precision and pride that would be the envy of any facilities employee. The electrical lab allows for full-scale installation mock-ups, and the HVAC lab not only provides for the understanding of various systems, but uses the building’s primary cooling system as yet another teaching tool. The diesel lab at the rear of the building has multiple semi-truck cabs inside the laboratory plugged in like Neo in the Matrix before he wakes, a 1965 “POS” providing reference adjacent to modern computerized engines. And, of course, all of this can change as the technologies do.

The design team naturally gives great credit to the client, and especially to Jones. “If it doesn’t come from the client, you can’t force it,” says Marsha Bowden, AIA. The restraint, even if mandated, is laudable. Nothing here feels forced; it is designed in the purest sense, in that nothing is included that need not be.

Jesse Hager, AIA, is a principal of CONTENT Architecture and an adjunct professor at the University of Houston.