Y Not?

A facility for engineering and technology education serves as a nexus of innovation for a community college.

Location Houston

Client San Jacinto College

Architect Kirksey Architecture

Contractor Tellepsen Builders

Civil Engineer Duplantis Design Group

Structural Engineer Walter P Moore

MEP Engineer JonesDBR

Acoustical Engineer Jaffe Holden

Program Manager AECOM

Landscape Architect KW Landscape Architects

The San Jacinto College Engineering and Technology Building features unconventional structural and sustainability strategies that support new ways of learning for students as they receive vocational training or take foundational courses before moving on to a four-year university. The 74,000-sf state-of-the-art facility houses engineering, math, computer science/information technology, engineering design graphics, and biomedical equipment repair technology programs. Contained within the building’s two stories are a maker space, labs, specialized classrooms, and spaces for academic support. Although the center opened during the emergence of the COVID-19 pandemic in 2020 when classes were virtual, the college immediately put the building’s new maker space to use, creating hundreds of 3D-printed brackets for face shields to send to community healthcare leaders.

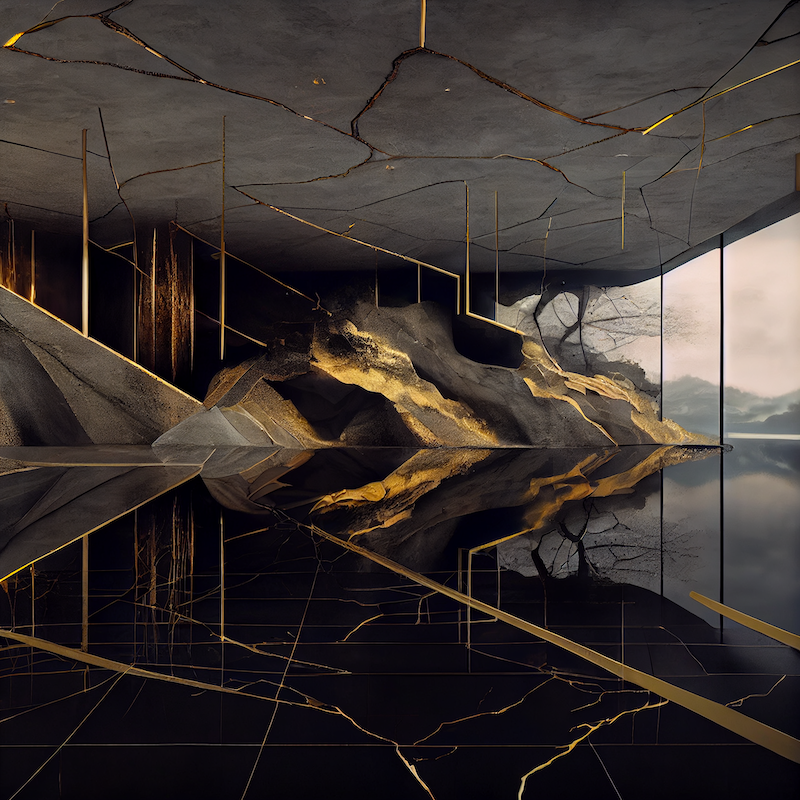

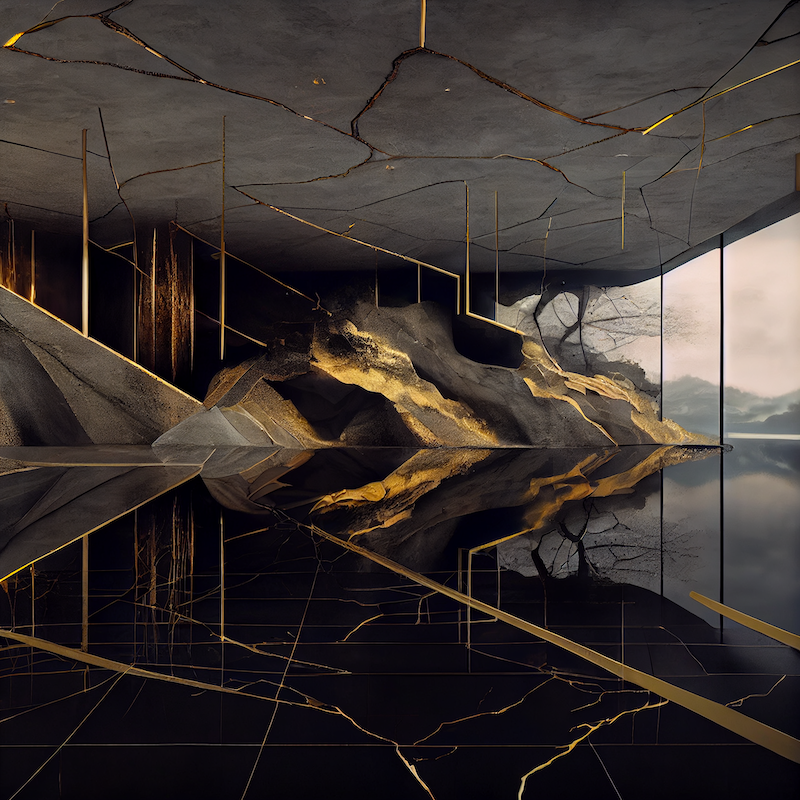

A primary question driving the project was how to create an innovative building that also blends with the campus. “How do you fit in with the context while also providing something that is more modern?” asks Michelle Giuseppetti-Old, AIA, associate vice president and designer at Kirksey. The building facade responds to the campus through shared material and color palettes, but the special formwork and varying finishes of light and heavy sandblast on the precast concrete panels create a distinctive, textured appearance through their thin vertical striations. Tall windows complement the vertical pattern while bringing ample light into interior spaces.

The Kirksey team was cognizant of both the budget and occupant needs as they carefully picked where major innovative moments would happen within the building — the large entry lobby being one of them. Kirksey received an AIA Houston Design Award in 2020 in the Divine Detail category for the structural innovation of the Y-columns used in the entry space. The dynamic form of these bifurcating columns not only reimagines structure but also prioritizes useable space and visibility. Rather than two columns handling two loads, the geometry became a single element. Compression and tension were studied to achieve the award-winning structure that redistributes two loads on one foundation point by shifting the arms of the column. Although the cast-in-place concrete columns use custom formwork and rebar, the repetition of these elements made them more cost effective. Notably, the columns had to be poured before the foundation to ensure they were in the correct positions. One of the three columns was pulled outside the envelope to showcase this feature on the exterior of the building.

The lobby entrance is intentionally ambiguous, meant to foster a sense of discovery while providing a secure entry familiar only to students and faculty. The space features high-performance glazing in the form of two walls of adaptive electrochromic glass to control light and heat. Each window automatically adjusts based on exterior heating and light conditions, becoming more tinted on a bright day and more translucent when the sky is overcast. The windows are also programmable, allowing building operators to override the self-adjusting systems as desired.

Another unique feature within the lobby is the stair to the second floor. Kirksey worked closely with the structural engineers at Walter P Moore to achieve this engineering feat: curving stairs with no vertical support. While standing beneath the stairs, I could see the bare bones of the structure holding up the precast concrete steps, just as a spinal column supports ribs. The load is carried from the floor and through the spine, then connected to the second-floor slab. While a conventional stair could have taken the same curving form, an out-of-place column would have claimed its space in the lobby.

From the second floor, I looked down into the double-height space of the Innovation Center. This maker space consists of a spacious collaboration area at the center flanked by rooms on both sides, including a 3D-printing lab with more than 10 printers, a wood shop, a metal shop, two student huddle rooms, and secure rooms for lockers, tools, and a plotter. An outdoor project area provides students spaces for spray-painting, welding, and cutting larger pieces of wood. The central collaboration space offers areas for lectures and classes, as well as room for students to collaborate and build.

The layout is organized so that students can produce in the smaller shops then assemble in the larger collaboration area. Mobile marker boards and tables on wheels allow the space to be reconfigured for lectures or for breakout groups. Along with the Y columns, the students and faculty have coined the term “Y lights” for the Innovation Center’s large overhead lights, due to their three-spoked form. “Why are we stuck on the ‘Y’? Because that space is all about the why or why not,” jokes Kevin Morris, dean of business and technology at the San Jacinto College South Campus.

The many windows between spaces create a continuous sight line between the lobby, Innovation Center, and outdoor project area. When occupants enter the lobby, they are greeted by a view into the maker space to the right as a way to immediately pique curiosity. This central block can be seen from both entry points along the east and west facades at the north end of the building, a design move intended to connect this college to a planned future Engineering and Technology development. The architects were also conscious not to design a traditional back to the building as another way of ensuring the building is prepared for the next phase of expansion.

The entire building itself serves as a teaching tool through its progressive structural elements and sustainable strategies. Rather than restricting learning to the classrooms, students can also learn from the exposed structure and construction details as they walk through the building. The corridors have interior windows into all the labs and studios with the intention of putting learning on display.

While all of the classrooms along the building perimeter include exterior glazing, the classrooms within the building’s core need to receive natural light in a different way. Kirksey turned to another energy-efficient lighting strategy: solar tubes. These tubular daylighting devices reflect sunlight into the spaces through a series of mirrors and can be controlled by a dimmer switch. As we walked through an open study space on the second floor, only a few solar tubes were needed to light the entire space; artificial lights were not even needed at the time. “On a bright day, you almost have to turn it down a little bit because it gets too bright, observes Dean Morris. “Most people can’t tell it’s not an LED light.”

The faculty offices can be found along the south side of the building at the end of the rows of classrooms. In between the classrooms, labs, and offices, students are provided with informal gathering and breakout spaces. The classroom labs are identical in layout, but the professional fields they are intended for is evident through their furnishings — from biomedical equipment to physics formulas scribbled on the whiteboards.

The other hands-on labs include facilities for X-ray/CAT scans and computer aided design and drafting (CADD). Here, students within the biomedical field learn to repair and maintain all kinds of medical equipment, from hospital beds to infusion pumps. All of the labs have a teaching wall with an abundance of storage along each side and utilize rolling desks to create a flexible space so that professors can walk around the classrooms as opposed to lecturing at one end.

At the top of the lobby’s curving stair, an interior window looks onto a classroom that contains several computers along the back wall and a wide empty space in front of them. This turned out to be a room for augmented and virtual reality (AR/VR), designed with enough space to prevent students and faculty from hitting walls or other objects in the room while they wear AR/VR headsets. The vast space can also be used for robotics learning in the future. The next room we visited was a 360-degree classroom (designed for an instructor to present from the room’s center rather than at one end) with three tables — each equipped with TV screens — located along the perimeter. Professors and students can connect to each TV so that their presentations are easily viewable by everyone versus on only one screen, as in a traditional classroom layout.

The Engineering and Technology facility has been thoughtfully planned and executed. The students and their needs were prioritized through lighting strategies, breakout spaces, resources for hands-on learning, and more. In addition, the building incorporates moments of learning through the expression of the structure and systems, expanding the way students can learn and succeed. As Giuseppetti-Old declares, “Whether you understand that you’re learning or not, it’s happening.”

Pooja Desai is a fifth-year architecture student at the Gerald D. Hines College of Architecture and Design at the University of Houston and a designer at Protolab Architects.

Also from this issue